About Global Lift Used Forklifts Glendale

Global Lift Glendale - Regardless whether you have a new forklift fleet or second-hand forklifts, your equipment needs to be maintained to guarantee safety and productivity. Careless forklift operation could result in additional costs because of abuse and damage. There are simple ways to identify operator practices which indirectly contribute to costs related to the wrong operation of Caterpillar lift trucks or forklifts. The tips below will truly help you reduce operating expenses while ensuring a long life for your equipment.

Regardless whether you have a brand new forklift fleet or used forklifts, your machine has to be maintained to guarantee productivity and safety. Careless forklift operation can lead to added expenses due to abuse and damage. There are easy ways to identify operator practices that indirectly contribute to expenses associated to the wrong operation of Caterpillar forklifts or lift trucks. The tips below would help you lessen operating expenses while ensuring a long life for your machine.

Causes Of Forklift And Facility Damage

Incorrect Forklifts. For the efficient and safe performance of a forklift, it is essential to select the right lift truck equipment for the application. One of the most common mistakes is utilizing the wrong type of forklift or alternatives for the particular job. Machines can suffer premature wear and tear. Components can be subject to failure. Make sure that the lift truck is fitted with the right tires and that they are not worn.

Improper Forklift Operating Practices. A common cause of impact damage is incorrect forklift operating practices. Damage to machine, facilities or product could happen while navigating around things. A congested work place lends itself to impacts. For example, pushing pallets, called "Bulldozing", could damage the transmission and wear tires.

Unsafe Forklift Speeding and Lifting. Incorrect lifting practices can lead to personal injury and equipment damage. Common errors comprise lifting very high and traveling very fast. A load which is too heavy can cause the forklift to tip over. The operator should make sure that the forks are level.

The forklift is a material handling equipment used to lift and move loads from one location to another. Each forklift part has a specific function. Different parts can be utilized to move the load vertically or horizontally.

The forklift mast refers to all the parts that lower and lift the load. There are different kinds of masts used for lifting loads to different heights: triplex, quad, simplex and duplex.

Forklifts have four various ways of being powered: gas, electric, diesel and propane. The battery is situated in the cab beneath the seat. The propane tank is on the back of the truck. The fuel tank on gas and diesel forklifts is under the back of the truck.

Situated within the center of the truck is the forklift cab. This is where the operator sits and accesses all the informational gauges and controls. The gas pedal, steering wheel, lifting controls, tilting controls and brake are all situated inside the cab.

The truck frame carries all the largest parts of the forklift, like the counterweights, which are located at the back so as to stop the truck from tipping when loaded. The frame consists of the overhead guard which protects the operator. The undercarriage holds the driveshaft, axles and wheels.

On the rear of the forklift is a counterbalance, that allows the forklift to lift very heavy things. The counterbalance gives balance so that the machine will not tip over while carrying and moving heavy cargo. Forklifts are rated according to their load capacity. A small forklift which can carry 1800 kilograms weighs around 4000 kilograms, which is equivalent to two full-size pickup trucks. The largest forklifts could carry stuff as heavy as 36,000\thirty six thousand kilograms.

In operating a forklift, there are lots of safety issues. For instance, travel in reverse while driving down a ramp. You should also haul a load in reverse if the cargo is bulky and interferes with vision. Operators should know how to safely mount the lift utilizing the "three-point stance." This includes putting the right hand on the back of the seat, while holding the upright of the safety cage using the left hand and placing the left foot on the step. Never jump out of a forklift even in a tip over. It is safer to stay inside the confines of the lift. Any slip or fall on a forklift could cause serious injuries.

Forklifts are considered indispensable tools in lots of businesses since they can be utilized to efficiently and quickly load and unload products and materials safely and with little physical exertion. Pedestrian safety is a primary consideration when operating in public spaces. Operators should always give pedestrians the right-of-way. A forklift should never be driven on a highway or on uneven surfaces. The driver should have a seat belt tightly fastened all the time while driving.

Forklifts are an essential tool for the cultures which either consumes or makes mass-produced products. Forklifts would continue to remain necessary pieces of equipment for companies. OSHA oversees compliance standards for companies that use forklifts and provides protocols for certifications and licensing. The Forklift Rodeo is an entertainment event intended for operators and other employees that includes an obstacle course and other entertaining spectacles.

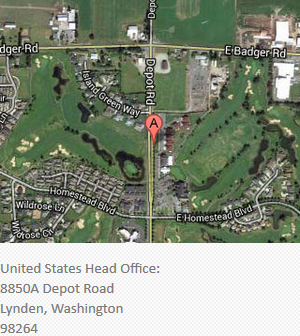

Contact Info

Questions or Comments